|

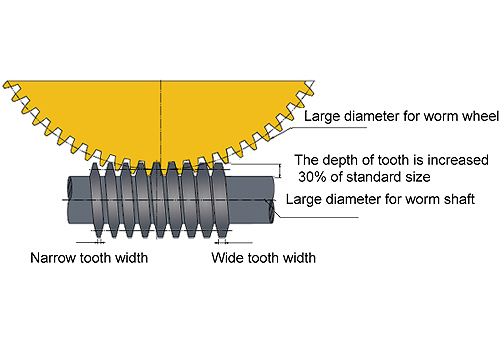

| The Matching Schema of Dual Lead Worm Wheel and Worm Shaft |

| |

|

| |

| ‧ |

Surface contact between in worm wheel and worm shaft can be reached 35%~45% suitable for heavy cutting and continuous processing

|

| ‧ |

Good wear-resisting, there is no need to adjust backlash at least 1~2 years |

| ‧ |

Indexing accuracy class is maintained |

|

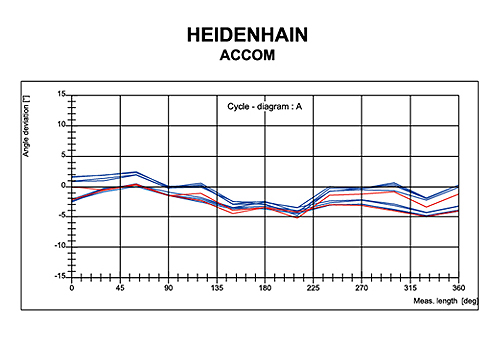

| Indexing accuracy class for CNC Rotary Table |

| |

|

| |

| ‧ |

Indexing accuracy class: 10(sec.) (standard 15 sec.)

|

| ‧ |

Repeatability: 4 (sec.) |

| ‧ |

According to ISO 230.2 standard of inspection which can be qualified to Aeronautics and Military Industry. |

|

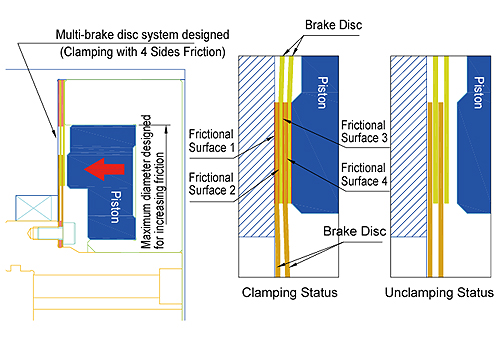

The Schema of Brake System

Clamping force is increased 2~3 times if compare with other brands of company |

| |

|

| |

| ‧ |

Multi-brake disc system designed (Clamping with 4 Sides Friction) |

| ‧ |

Creating clamp torque 200 kg•m from pneumatic source : 5kg/cm² |

| ‧ |

Compact & high durability designed; there is no liftingup situation during rotating |

|

| The Schema of Advantage Bearing System |

| |

|

| |

| ‧ |

3 sides constraint designed, supporting force is greater than same dimension of Cross-Roller Ring (bearing) above 2 times |

| ‧ |

Dual bearings designed, extending diameter suitable for heavy cutting |

|

| Indexing accuracy class for Hirth Coupling |

| |

|

| |

| ‧ |

Indexing accuracy class: ±3 (sec.) |

| ‧ |

Repeatability: ±1 (sec.) |

| ‧ |

Contact rate of Teeth surface can be reached 90% |

|

| Gear ratio |

| ‧ |

To match high speed machine center (60m/min) with high speed CNC Rotary Table

|

| ‧ |

Gear ratio 90:1 can be reached 33rpm (motor:3000rpm) |

|

|

|